knife making(Sheath knife) |

May. 4/2016 In around 1986, I was absorbed in a knife making.An incomplete knife has come out of the drawer of a workbench. That slept for nearly 30 years. The shape of the handle seemed fascinating, so I decided to complete it. |

|

|

|

1.Grind by #240, #400, #600, #800, #1000 and #1200. |

2.I commissioned to quench in a company in Osaka. |

|

|

|

|

3.By Rockwell hardness, 60. |

4.Grinding with from #600 to #12000. |

|

|

|

|

5.Buffing. |

6.The next is joining of a hilt, but a blade face is ground in front of it. I think the material is probably SUS304. |

|

|

|

|

7.Rivet by a pin of 2.6mm. |

8.A hilt was fixed tightly. |

|

|

|

|

9.The handle material is iron wood of thickness 8mm. |

10.This is a black fiber spacer. |

|

|

|

|

11.Ground the hilt by a file. and, Protect in a blade part so as not to damage. |

12.Glue one side of the handle. |

|

|

|

|

13.Drilling 4mm in the handle material from side of the knife. |

14.Drilling a spot-face of 8mm. |

|

|

|

|

15.Glue a fastener bolt and the handle together. A bolt is M4. The material is sus304. |

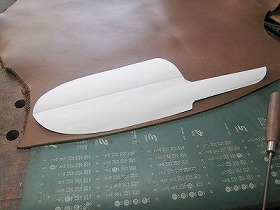

16.Make the pattern of the sheath by paper. |

|

|

|

|

17.Make sheath with 3 mm of leather. Marking around of the pattern. |

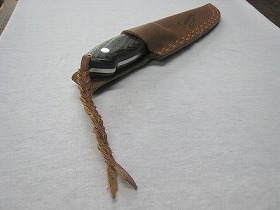

18.Mark the drilling position by the divider, and drilling the 1.5mm by the self-made high-speed drilling machine. Sewing, This time, I used the Cremona thread of yellow and red. |

|

|

|

|

19.Making a string of thong Hole. used a leather with a thickness of 1mm. |

20.Dipping a sheath in lukewarm water for about 10 seconds.Then, insert a knife slowly and you match it with the sheath. |

|

|

||

Put an edge to the knife. I believe the knife is most beautiful tool. |

||

|

||

I made these knives 29 years ago. |

||