Adjustable stop back |

Mar. 12/2017 I made adjustable stop back for cross cut sled in the table-saw BT3100. Drawing |

|

|

|

1.The material is rubber wood. |

2.Making a groove for the guide plate by using a router.Width 6mm,Depth3mm. |

|

|

|

|

3.Drilling 6mm. |

4.Drilling 8mm. |

|

|

|

|

5.Drilling by the 16mm fostner bit. Depth 9mm. |

6.Drilling 10mm. |

|

|

|

|

7.Make a collar using the SUS304 pipe.ID8mm,OD10mm,Length19mm. |

8.Insert the collar with the vise. |

|

|

|

|

9.Make a washer. Drilling the 8mm to washer for for M6 bolts. |

10.Marking the outline of the U nut to the awing arm. |

|

|

|

|

11.Drilling by the 1/2" fostner bit. Depth 9mm. |

12.Carved in a hexagonal shape with chisel. |

|

|

|

|

13.This knob to lift the swing stopper. Material is ebony. |

14.Make a T-groove to the cross cut sled. First, width 6mm, depth 12mm. |

|

|

|

|

15.Then, Make a T-groove using a straight bit of a diameter 1/2" * length 1/4". |

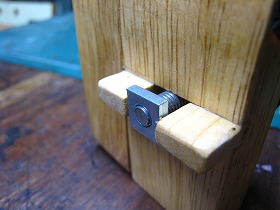

16.The back side of the main body. M6 square nut and the guide parts. |

|

|

||

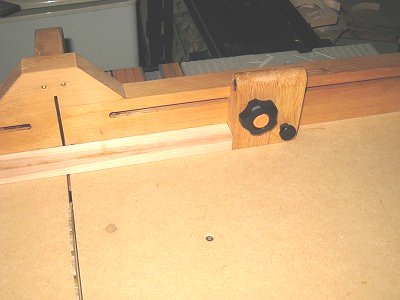

Mounted on the right side of the cross cut sled.Photos are taken from the opposite direction of the worker. Therefore, the left side and right side are reversed representation. |

||

|

||

Lifting a stopper for prevent kick-back, before cutting the works. |

||

|

||

Mounted on the left side. Stoppers do not have to swing. |

||

|

||

Fixing a U nut with epoxy adhesive.It will be adjusting the rub of swing board by the M8 bolt. |

||