Vise rack stop |

Dec. 10/2017 I made vise rack stop. This device is designed to help prevent racking when clamping work at one side of a vise.Drawing |

|

|

|

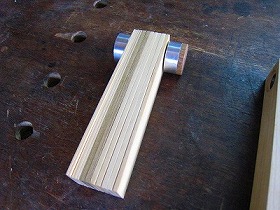

1.Material is poplar. Cut it to 1.5mm thick and 3mm and 7mm. |

2.Cut it to 120mm length. |

|

|

|

|

3.Drilling 7mm to a workpices of 1.5 mm thick and 3mm. |

4.Incert the workpiece an aluminum pipe with a 7mm OD, Sanding the end face. |

|

|

|

|

5.Take out only one of the 7mm thick workpieces groups. Drilling in a depth of 1.5mm with a 16mm OD fastener bit. |

6.Next, Drilling 12mm. |

|

|

|

|

7.Drill 12mm to a other workpices of 7mm thick. |

8.Incert the workpiece a SUS pipe with a@12mm OD, Sanding the end face. |

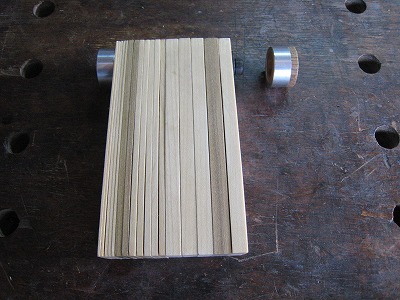

|

|

|

|

9.Cut the aluminum pipe to 29.5mm length. |

10.This is a SUS pipe with a 12mm OD. Extend the inner diameter to 10.5mm by a length of 5.5mm.The head of the M6 cap screw enters this hole. |

|

|

|

|

11.Make a long nut. This nut into the 10mm OD SUS pipe. First, a center drill. |

12.Next, Drilling 5mm. |

|

|

|

|

13.Last, Tapping M6. |

14.Glue the long nut to the SUS pipe. |

|

|

|

|

15.This is a part for the magnet to put on the SUS pipe. Sit back with a diameter 6mm and a depth 3mm on a 10mm SS material. |

16.Glue a neodymium magnet to the part. |

|

|

|

|

17.Glue a SUS pipe to a 7mm thick spacer. Using epoxy glue. |

18.Glue a neodymium magnet parts into the pipe. |

|

|

|

|

19.This is an aluminum ring with a diameter of 24mm and a width of 11mm. Spot face with a diameter 19mm and a depth 2mm. |

20.Glue a M6 washer to the ring. |

|

|

|

|

21.This is a core to put inside the cap. |

22.Turning the core end face. |

|

|

|

|

23.Glue a core to the aluminum ring. |

24.Neodymium magnets are glued inside the core. |

|

|

|

|

25.17 spacers are finished with watoco oil. |

26.Insert five spacers into the SUS pipe, the pipe will out 0.5mm. |

|

|

|

|

27.Insert 1.5mm and 3mm spacer into 7mm aluminum pipe and tighten with aluminum ring with washer attached.(left side). 7mm spacer completed by tightening with a cap screw.(right side). |

28.Cover the screw-head of 1.5mm + 3mm spacer with a magnet cap. |

|

|

||

Connect a 7 mm spacer to the 1.5 mm + 3 mm spacer with magunet. |

||

|

||

Cover the screw-head of 7mm spacer with a magnets cap. |

||