Positioning guide for FABOOL laser mini |

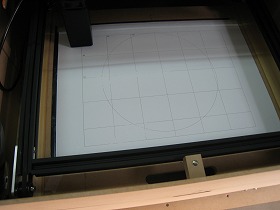

Apr. 1/2018 I installed a right angle positioning guide on the enclosure slide table. |

|

|

|

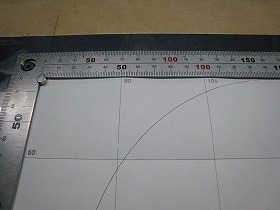

1.Draw a grid on the PPC paper in increments of 50 mm with data for origin adjustment.You can download origin adjustment data from here.Use origin adjustment Data at your own risk. |

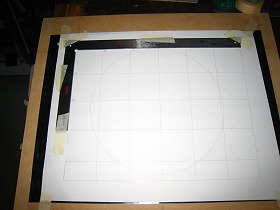

2.Next, place the square gauge on the paper and check whether the position of 0 mm, 50 mm, 100 mm, 150 mm is not differenced.If it is not differenced, fix the square gauge with masking tape. |

|

|

|

|

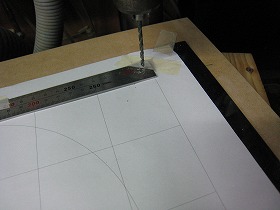

3.Drilling 4mm. |

4.Remove the square gauge and Drilling the 6mm for the M4 insert nut. |

|

|

|

|

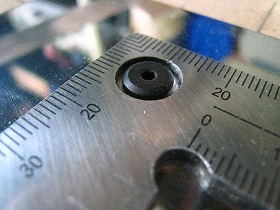

5.Made spot faceing 8.5 mm to sink the insert nut. |

6.The M4 insert nut screw in bord. |

|

|

|

|

7.Made spot faceing 12 mm to sink the head of M4 cap screw. |

8.Attach the square gauge with M4 low head cap screw. |

|

|

|

|

9.Finally draw the grid with the data for the origin adjustment and confirm that each position matches. |

10.Although the inner scale is carved on the long side of the gauge, it is not on the short side. So fill in the inner dimensions with the Tepra. |

|

|

|

|

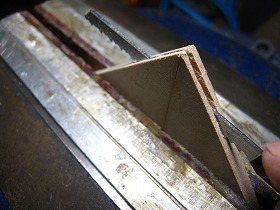

11.Made square guide and straight guide with MDF board. The material is 4 mm MDF, 6 mm neodymium magnet and 1 mm thick aluminum plate. |

12.The corner is miter joint. Put aluminum joint to increase the strength. The groove was just 1 mm wide when cut with jig@saw teeth. |

|

|

|

|

13.This is 1 mm thick aluminum plate bonded. |

14.Use 3 neodymium magnets to increase adsorption strength. |

|