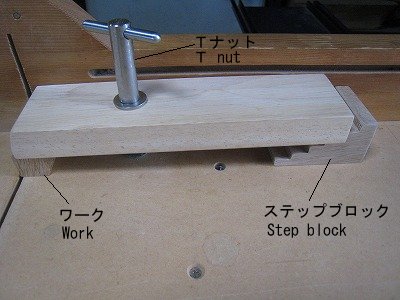

Step clamp |

Jun. 21/2020 I made a step clamp for cutting small materials with a table saw. It can work safely with this..Drawing |

|

|

|

1.The step block was made of Japanese ash. Make the stairs by partially cutting with a table saw. |

2.The arm is a glued laminated wood. Counterbore with 20mm fastener bit. This is the space where the M8 nut of the stud bolt retreats. |

|

|

|

|

3.Drilling 8mm. |

4.Drill a 3mm pilot hole for the where the T-bar enters. |

|

|

|

|

5.Drilling 6mm. |

6.Finish of the end face. Because it is SS400, it can be sharpened quickly. |

|

|

|

|

7.Marking with center drill. |

8.Drill a 6.5mm pilot hole for M8. |

|

|

|

|

9.M8 tap. At first, tapping with the tailstock while pressing can set the screw straight. |

10.Tapping M8. |

|

|

|

|

11.Cut a 6mm round bar for T bar to 50mm length. |

12.Cut M8 long screw to 71mm. |

|

|

|

|

13.Completed parts. |

14.The stud nut fits into the hole in the arm. |

|

|

|

|

15.25mm spot facing for T-nuts on cross cut threads. |

16.The M8T nut is pushed in. |

|

|

||

Screw stud bolt into cross-cut thread if used. |

||

|

||

This is the state where the work piece is sandwiched. Even if the workpiece is small, it can be clamped safely. |

||