Pocket hole jig-2 |

Mar. 7/2021 I made an attachment for the pocket hole jig I made last time. This is used when joining large wooden boards.Drawing |

|

|

|

1.The material is laminated wood of rubber tree wood. |

2.Cutted out workpiece. |

|

|

|

|

3.Drilling 10mm on both ends of the slot. |

4.Cut with a scroll saw. |

|

|

|

|

5.Drilling 22mm to insert the PVC fitting of the dust port. A hole will be made in the board and the center of the board, so fix it firmly with a clamp. |

6.Make a dowel pin holes. It's removed the clamp because It put a dowel pin in one of the holes, but when it drilling a hole in the this side, fix it with a clamp. |

|

|

|

|

7.Cut a groove to the lid side with a 19 mm spherical bit. |

8.Similarly, make a groove to the main body. |

|

|

|

|

9.This is a member that serves as a side support for the drill guide. Drilling 5 mm on both ends of the slot. |

10.Cut with a scroll saw. A thumbscrew is inserted in this slot. |

|

|

|

|

11.After temporarily adhering the members, drill a 3.4 mm hole for fixing the side support. |

12.Counterbore for countersunk screws. |

|

|

|

|

13.Drilling in the opposite side support. |

14.Drilling to fix the main body and the rear stopper. |

|

|

|

|

15.Turning the tip of the TS socket 20 *13 to a diameter of 22 mm * 20 L. |

16.The socket should be glued only on the lid side with an epoxy adhesive. |

|

|

|

|

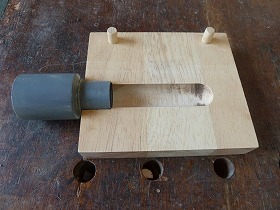

17.The upper surface of the assembled main body. |

18.The back of the main body. |

|

|

|

|

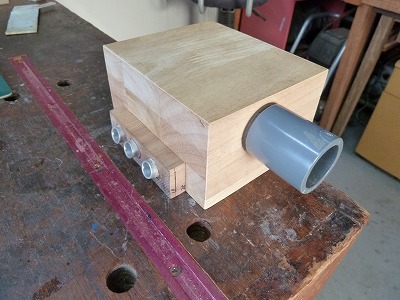

19.The state where the drill guide is inserted in the main body. |

20.With the top lid attached. |

|

|

|

|

21.The state where the drill guide is inserted all the way. |

22.The thumbscrew is on one side only. |

|

|

|

|

23.Adjust the position of the drill stopper according to the thickness of the work, using the marker of the drill guide as a guide. |

24.If you do not have a dust collector, you will need to remove the lid. |

|

|

|

|

25.When It remove the lid and look at it from the top,It can see a round hole in the back. Chips are discharged from here. |

26.Engraved the letters on the lid with a laser. |

|

|

||

Press the stopper against the work and fix it with a clamp. |

||

|

||

The drill guide is the same height as the side support, so it will not shift. |

||