Corner doweling jig |

Oct. 31/2021 I made a drilling jig to penetrate and fix the dowel in the corner of the frame or the small box.Drawing |

|

|

|

1.The material is rubber wood laminated lumber. |

2.First, cut it to a width of 60 mm with a table saw. |

|

|

|

|

3.Drill 6 mm on both ends of a 6 mm wide slot. |

4.Drill 3 mm at the four corners of the square hole where the drill guide block will fit. This is a process to make it easier to cut with a jigsaw and to make it easier to insert a guide block. |

|

|

|

|

5.20mm drilling of the center line confirmation window. |

6.Cut out a 6 mm long hole with a scroll saw. |

|

|

|

|

7.Similarly, use a scroll saw to cut out the square hole that insert the drill guide block. |

8.The notch in the square groove that contains the acrylic plate for the center line was made using a 5.5 mm thick plywood template. |

|

|

|

|

9.Use a 6mm bit to dig a 3mm deep groove. |

10.Use Japanese ash for the drill guide block. Cut 10 mm from the edge and process it into a T shape. |

|

|

|

|

11.Cut to a length of 53 mm. |

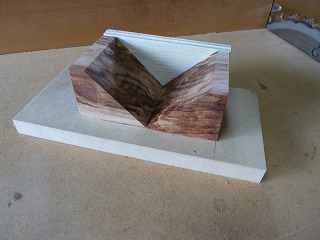

12.This is a 45 degree drilling jig made from offcuts. |

|

|

|

|

13.Bolt through hole 6 mm for fixing L-shaped bracket. |

14.Pilot hole for M6T-nut, 7.4mm. |

|

|

|

|

15.The T-nut can be pushed straight in by sandwiching it with a vise. |

16.There is no counterbore. |

|

|

|

|

17.Drill with a pocket hole jig. |

18.Fix it to a right angle jig and fix it with screws |

|

|

|

|

19.Glue a 9.5mm plug made with the round bar shaving jig introduced last month. |

20.When sanded there, it becomes a beautiful oval pattern. |

|

|

|

|

21.Place the drill guide block on the 45 degree drilling jig, align the drilling position, and fix the jig to the drill table. Now you can make a hole in the same position. |

22.For alignment, I used a thin taper reamer with a sharp point, which is used for center punch. |

|

|

|

|

23.Drilling for pipe 6*8. First drill 8mm holes. The depth is 40mm. |

24.Next, Drilling a 6mm through hole. |

|

|

|

|

25.Drilling for pipe 8*10. First drill 10mm holes. The depth is 40mm. |

26.Next, Drilling a 8mm through hole. |

|

|

|

|

27.Drilling for pipe 10*12. First drill 12mm holes. The depth is 40mm. |

28.Next, Drilling a 10mm through hole. |

|

|

|

|

29.Here, it was found that the outer diameter of the 12 mm pipe was about 12.5 mm. Therefore, Turning the outer diameter with lathe. |

30.Glue the pipe to the drill guide block with two-component epoxy. |

|

|

|

|

31.Grooving to insert the slide crosspiece into the main body.12mm width x 3mm depth. |

32.Grooving to bond the crosspiece to the L-shaped bracket.12mm width x 5mm depth. |

|

|

|

|

33.After adhering the pedestal for the plate that holds the drill guide block, Drilling 2.5 mm. |

34.Make a counterbore. |

|

|

|

|

35.Make a counterbore to sink the flange of the insert nut. Diameter 9 mm x depth 1 mm. |

36.Drilling 6 mm. |

|

|

|

|

37.Screw in the insert nut with a hex wrench. |

38.This is a fence to prevent the disposable board from falling. 2.5 mm drilling for mounting screws. |

|

|

|

|

39.Fix the fence under the L-shaped bracket. |

40.Attach a fence to the side in the same way. |

|

|

|

|

41.When the fence is attached, it becomes like this, and the disposable board does not fall or shift sideways. |

42.After cutting 3t of acrylic plate for the center line as shown in the drawing, cut the four corners to R3 with a sander. |

|

|

|

|

43.Drilling 2.4mm for mounting screws. |

44.Make a counterbore. |

|

|

|

|

45.Attach the acrylic plate to the main body and fill in the center line with a scribing needle. |

46.Then, a dented line enters like this. |

|

|

|

|

47.Trace over the line with a red pencil. |

48.Then, the center line becomes red and it becomes easy to see. |

|

|

|

|

49.This is the holding plate of the drill guide block.After marking the cutting line on an aluminum plate with a width of 20 mm and a thickness of 3 mm, a hole of 4 mm is drilled. |

50.Completed block holding plate. |

|

|

|

|

51.Fix the block retainer plate to the main body with screws. The plate that can be seen on the left side of the holding plate is a stopper to prevent the holding plate from rotating. |

52.Completed body, drill guide block, disposable board. |

|

|

|

|

53.The side of the main body. |

54.The back side of the L-shaped bracket. |

|

|

|

|

55.The back side of the main body. Can see the centerline scale and the back of the drill guide block. |

56.Looking at the centerline scale from the front side, it looks like this. |

|

|

|

|

57.The state where the drill guide block is inserted into the main body. |

58.The aluminum retainer plate is rotated 90 degrees and locked. |

|

|

|

|

59.I bought a middle size drill with a total length of 160 mm and a blade length of 100 mm from RAKUTEN for 6 mm and 8 mm drills. What you can see in the upper right is the stopper that I bought at MONOTARO before. |

60.When I measured the total length of the 10mm drill that I usually use, it was 140mm, so I think I can use it somehow. |

|

|

||

When making a dowel hole, fix the jig to the work with an F clamp. |

||

|

||

Please see the video for how to use it. |

||