I can't make the same one using the wood lathe. Because, X-Y slide table isn't attached to my wood lathe.

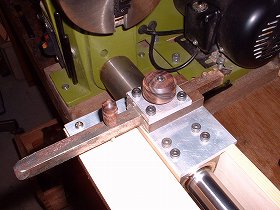

Therefore, I made the copy jig of the wood lathe.

The cylinder which I gathered was used for the slide part of this jig.

The cylinder which I gathered was used for the slide part of this jig. The drawing

This cylinder was "rod ress air cylinder."

I extracted the internal piston (powerful magnet).

Since the stroke was small, slider of the direction of Y was made personally.

Making of an angle and stem borrowed and processed the machine of a small ironworks.

The photograph is the aluminum plate of the material, the angle and the stem which I made in the small ironworks of neighborhood.

Other parts of aluminum was cut by handsaw and deleted with the file.

It is not difficult work. However, I was tired because the heat of late summer was sever.

The slide guide of the tool stand is using plywood.

Also, it is pasting the tape of Polyethylene to use for a threshold to slip smoothly.

Since the part was assembled, I assembled.

The knob for fixation of a tool holder and the knob attached to the pin for model trace were made from the red sandalwood.

The pin for trace is not contained in the drawing. A 2mm hole is made in a tool holder, and it stabs with a pin there.

The tool holder processed 10mm key material.

It can hold the byte of HSS now at a tip. This tool holder is made myself before.

I set 7mm square lumber for the model positioning to the table in front of setting a model.

and, It has sheet of Polyethylene to the part which touches a slide cylinder.

I operated it,and I think that I want to attach a knob to it.

As for the direction of Y, I used the plastic circle ball who was in the junk box and the direction of X is a knob with the kiwi size which myself made with the square lumber of the chestnut.

This photograph saw from the underside of the equipment.

The explanation to here is insufficient in the way of the set of the model.

Next time, set an actual model and let's introduce a way of using.