Threding-jig for the wood turning

Aug. 01/2004 I began to make a threading-jig for the wood turning. My lathe doesn't have feed screw. I thought of the mechanism of jig. Then, I flashed. "A works will be threading if it moves turning works." First, I was "Drawing" by CAD. Pitch of the screw is the same as the feed screw. Because collet chuck was 3/4'*16tpi, I decided to use this long screw. Please, refer to the drawing. . |

||

|

|

|

1.The material is a long screw, aluminum square block, an angle and so on. I made a screw at the ironworks of the friend. |

2.The part of aluminum was the ironworks of the friend, and it borrowed and turned a lathe. It's possible to cut smoothly by end-mill of 18m/m. |

|

|

|

|

3.I'm milling a side. |

4.I fixes on the block of iron by the hand vice. The under-hole of the M6 tap is ø5mm. |

|

|

|

|

5.I use a spiral tap. It is well sharpness. |

6.I made a knob for the X axis by lathe. I thought that it is aluminum but it was a duralumin. I heard it from my friend. |

|

|

|

|

7.I turned the end of thelong-screw for the X axis with the lathe in ø17mm. and,I tapped M6. |

8.I turned the end of the M12 long-screw for the Y axis with the lathe in ø8mm. |

|

|

|

|

9.The handle joins two grip balls of ø19mm by the bolt of M6. and with sleeve pipe. |

10.sees from the reverse. I did the upper and lower adjustment with the shim. |

|

|

|

|

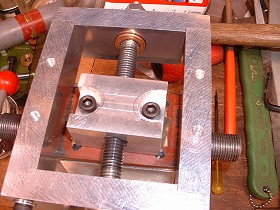

11.I seted a stand. |

12.I made thread-saw, shaving a Dresser by the Grinder. I make a true circle when I fasten up a Dresser with the bolt of M6 and turn it with the drill. The thread angle is 60degree. |

|

|

|

|

13.I assembled parts and I installed a jig in the lathe. and, I sets the shim of brass to the surface of the end of the slide part and I'm adjusts it to move smoothly without the crack. |

14.The backside. |

|

|

|

|

15.I chucked thread-saw on the lathe. |

16.To measure the movement distance of the X axis, I was set a scale. |

|

|

|

|

17.It is important to attach the principal axis and chuck of a lathe right-angled. Otherwise, when chuck is changed for a jig, a work sways. Then, I replaced with the washer and the nut for bearing adapters was put into the principal axis. |

18.I am doing a test in the thread. But,The test piece isn't beautifully threading. I thinks that it seems that there is a problem in the cutter. I threading for test. Next time, I will introduces the way of using jig with in the page of the turning works. |

|