VACUUM CHUCK |

Jan. 3/2007 First, I make Rotary Joint. However, I have not obtained the vacuum pump yet.Drawing |

|

|

|

1.This is a coupler.3TPM R3/8 of NITTO company. |

2.I turn the PT3/8 screw part of the coupler to ø12m/m. |

|

|

|

|

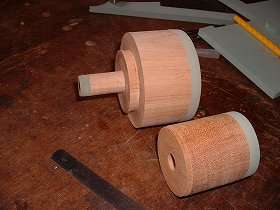

3.Next, I make the flange. The material is a rubber tree. |

4.The process of the housing which inserts bearing (#6001LLU). |

|

|

|

|

5.I am drilling to face plate for CAP screw. |

6.M5 tapping. Because face plate is cast metal, tapping is light. |

|

|

|

|

7.I adjust a wick using the dial gage. |

8.I assembled parts.The knockout bar can be used with the adaptor mounted. |

|

|

|

|

9.I gripped the coupler by way of experiment and turned the spindle.There was no vibration and it turned lightly. |

10.The coupler was assembled. |

|

Jan. 7/2007 Second, I made vacuum chuck adaptor.It is general to use the face plate.However, I designed chuck that was able to do mount Akisminstar.Drawing |

|

|

|

11.I made main body.I do not know the material of wood.It is very hard and dense. |

12.I stick a bubble neoprene sheet to the part which touches the spindle of WT-300 as the gasket.The shut-ability is quite good. |

|

|

|

|

13.I stick a bubble neoprene sheet to the mouse in opposite, too |

14.The right side is a small size attachment. |

|

|

|

|

15.Way of using a small size attachment. |

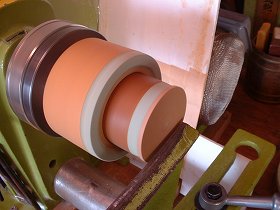

16.Making a large size attachment.I cut a ditch in the direction of the circumference, it make the flow of air. |

|

|

|

|

17.I use a trimmer to cut a ditch for a radiation line.I use the straight bit of 10m/m. |

18.This attachment is not a midair. I think that there is not apprehension to damage even if it absorbs a plate with big diameter. |

|

|

|

|

19.I insert it in the body of vacuum chuck when using big attachment. |

20.This vacuum chuck is possible to use it for three kinds. |

|

Mar. 1/2007 I got Vacuum pump by the recycle shop. I connected pipeing and I tested. Piping |

|

|

|

1.This model is MP-40-V by Mitsumi Co. Suction is 57L/min. Max vacuum is 6.3KPa. |

2.This is the suction filter of the pressure regulator valve. The element is a filter for the tropical fish water tank. |

|

|

|

|

3.I am making the bracket of pipe. |

4.A pipe is inside. |

|

|

|

|

5.I assembled a bracket. I used a ball valve for the pressure regulator. |

6.Around the rotary joint. I put a wood support to the joint.It is possible to remove it simply. |

|

|

|

|

7.The pressure gauge is mounted in the position that sees easily.I think that the pressure confirmation is important. |

8.I tried for the turning of a madrone burl. The pump has an enough sucking force. I think that it can use it at ease even by a big diameter. |

|

|

|

|

9.It is ring chuck type. |

10.It is the vacuum chuck which used a face plate. |

|