Mini Drill Press |

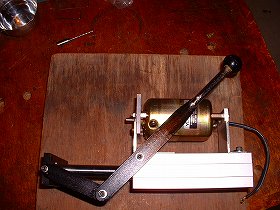

Oct. 09/2011 I made a Mini drill-Press,using a mini motor of sewing machine. |

|

|

|

1.This is mini motor.100V,60W,4500rpm. Made by YAMAMOTO DENKI. model YM-43. |

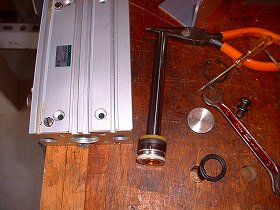

2.This is air cylinder.Made by CKD. Model STLM25-100. I use it for the movement of the motor. It has a guide to both sides. |

|

|

|

|

3.Remove the O ring. Then, The move of the rod becomes smooth. |

4.Making a bracket which fixes a motor. The aluminum angle. 50*50*3t. |

|

|

|

|

5.Assembling a shaft end part. |

6.Making a coupling for drill shaft. |

|

|

|

|

7.Drilling a 1.8mm. |

8.Drilling a 6mm for motor shaft. |

|

|

|

|

9.Tapping. The drill side is M3 and the motor side is M4. |

10.Tapping M5. |

|

|

|

|

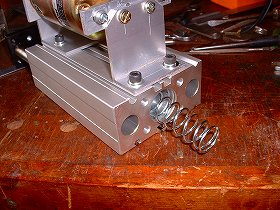

11.View the fan end of the motor. Installed in the cylinder with the 50 mm angle and flat bar. |

12.Side view. |

|

|

|

|

13.Putting a coil spring in the cylinder rod. This spring wire 1.6 mm ,OD 20 mm, free length of 105 mm. |

14.Doing a lid with the snap-ring. |

|

|

|

|

15.Doing the preparation to install a link mechanism. |

16.These are the part of the link mechanism. Plate is 3 mm thickness,18 mm width,SS400. |

|

|

|

|

17.Completing the link mechanism. |

18.Next, making the base plate. The material is 30 mm plywood. |

|

|

|

|

19.Setting a rubber leg to the reverse of plate. |

20.Using a limit switch for the power switch. It's a upper right. |

|

|

|

|

21.Making the stand-parts for limit switch. |

22.Bending it, and fixing a plate of aluminum. |

|

|

|

|

23.Wiring. The motor On in the cylinder descent. |

24.It was complete. |

|

|

||

This drill-press is very silent. |

||