I exchanged the whetstone of the one in WA. Then, I seted sharpening-jig.

I exchanged the whetstone of the one in WA. Then, I seted sharpening-jig.April 17/2005

I got a grinding jig from the my friend, who is working for the business company of the tool.

I got a grinding jig from the my friend, who is working for the business company of the tool.

It becomes height and the mechanism which can do an angle adjustment with two handles.

It is easy to use.However, some reorganization points were found out.

Next time Let's introduce.

I got a grinding jig from the my friend, who is working for the business company of the tool.

I got a grinding jig from the my friend, who is working for the business company of the tool.It becomes height and the mechanism which can do an angle adjustment with two handles.

It is easy to use.However, some reorganization points were found out.

Next time Let's introduce.

Sep. 13/2003

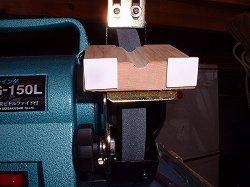

To grinding a turning tool, grinder is necessary.

Then, the jig which suited a tool is necessary.

I attached the polish jig for gouge in both the phi150x19mm head grinder purchased for 1980 yen at the tool shop.

I put a jig for bowl gouge to whetstone in the right.

I remodeled the tool rest of the grinder attachment and put a wooden table.

I cut a slot with U bits in the center, and took care to have not swayed right and left.

Moreover, a front plywood is the stopper made not to slide down when other jigs are put.

Left-hand side attached the jig which grinds a skew.

Since the table inclines to right and left, the angle of a skew can be put together easily.

To grinding a turning tool, grinder is necessary.

Then, the jig which suited a tool is necessary.

I attached the polish jig for gouge in both the phi150x19mm head grinder purchased for 1980 yen at the tool shop.

I put a jig for bowl gouge to whetstone in the right.

I remodeled the tool rest of the grinder attachment and put a wooden table.

I cut a slot with U bits in the center, and took care to have not swayed right and left.

Moreover, a front plywood is the stopper made not to slide down when other jigs are put.

Left-hand side attached the jig which grinds a skew.

Since the table inclines to right and left, the angle of a skew can be put together easily.