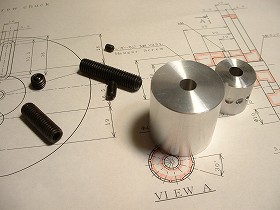

Eccentric Screw Chuck |

July 23/2006 I made Jig to make eccentric works.I think that it is possible to use it more simply than 4-jaw chuck.Drawing |

|

|

|

1.I make a disk part.The material is a duralumin with 10 mm thickness.The duralumin is moderate hardness and the shear-ability is outstanding. |

2.I manufacture using WT-300 from here.I remove Joe of the Axminster and I install a disk.I confirm a center using the dial gage. |

|

|

|

|

3.center hole with the center drill. |

4.I open hole ø6.8m/m under M8. |

|

|

|

|

5.Tapped M8. |

6.Next, I manufacture a boss. |

|

|

|

|

7.Tapped M8. |

8.Next, I tapped of M5 at the boss of the side of the turn.This is for the hollow setscrew. |

|

|

|

|

9.I glue together the bolt of M8~30L to the fixation boss.After that, I drum the spring roll pin of ø3m/m. |

10.I force the hanger bolt of ø8m/m~40L into the turn boss. |

|

|

|

|

11.All parts were complete. Next, a assembly. |

12.I turn the rotation boss 30degree and mark it by the needle. |

|

|

|

|

13.I mount it in the Axminster chuck which removed Joe. |

14.I tried. There is a eccentric of 12 mm and it is twisted. It is scary though it is interesting. |

|

|

|

|

15.The material is beech. |

16.I set a number to know a turn position. |

|