Works of wood turning [Page1] |

Lathe & Tool | |

|

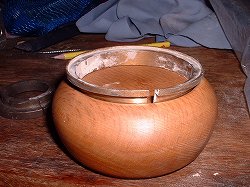

July 06/2003 Nuts-Bowl  Generally, Expert are chucking for material by the collet chuck and step jaw when making a bowl and a dish.

Generally, Expert are chucking for material by the collet chuck and step jaw when making a bowl and a dish.But, Those chuck are expensive. Of course, I don't have. The works has a damage when I used a scrolling chuck to direct for chucking works. I put in thin board of brass when I was chucking it. However, the damage didn't pass away. Therefore, I made a "insert-ring" in the photograph. The material is brass. I cut one place of "insert-ring". Then, the "insert-ring" is elastic and It can do correct chucking for works. Also, the works doesn't have a damage, too. I will make any kind of jig next time.

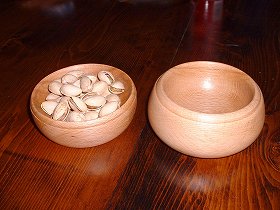

Woods: beech. 100mm Dia * 47mm Tall. with Watco Finishing oil. June 28/2003 Bowl(small)  I bought a band-saw.It's BS-10K by REXON.It is made in Taiwan and it is similar to DELTA.

I bought a band-saw.It's BS-10K by REXON.It is made in Taiwan and it is similar to DELTA.I was sawing hard wood using this band-saw.

Woods: beech. 100mm Dia * 45mm Tall. with urethane finishing paint. June 08/2003 mug cup  I bought the timber of the hardwood from WOODY, COSMOS.

I bought the timber of the hardwood from WOODY, COSMOS.First, I cut off beech to the hexagonal-shaped and screwed it on the face plate of the lathe.

Next, I begins to turning an outward form and I turning a part in the bottom circularly that it is possible to grasp with the scroll chuck. I uses that scrolling chuck. for the inside. I got an often strong kick. In such a case, I wants S type tool rest.

Because it was a mug cup, I used the urethane finish. I branded to the bottom of cup. May 11/2003  Because I bought a woodcraft lathe, I became the sickness of the "I wants to turn anything" symdrome.

Because I bought a woodcraft lathe, I became the sickness of the "I wants to turn anything" symdrome.I attempted to turn a Japanese cedar. because I was ordering the timber of the hardwood but it didn't arrive yet. It is my maiden work. Tentatively, it is using as the coaster for the can beer with oil finished.

|