Wood turning (Lathe & Tool) |

Go to Works | |

|

Vibration |

Tailstock |

Spindle improve1 |

DrillChuck |

Ring |

Grinding Jig |

Collet Chuck |

Copy Jig |

Ring Chuck |

Buffing | |

|

Threading |

Tool rest |

Bantam chuck |

Spindle lock |

Ssanding Jig |

Spindle improve2 |

Router Lathe |

W-angle cutter | |

|

Button jaw |

Hadle of tailstok |

Chattering tool |

Box rest |

Inverter |

Eccentric screw chuck |

Wagon |

Two-Jaw chuck | |

|

May 11/2003

The wood turning In Japan, it is called "Rokuro". I was interested in turning from before. However, I did not have the courage which purchases an expensive woodwork lathe.

In such a case, I bought WT-300 of the Nakatomi industry at the tool shop. A similar lathe is sold from the Rexon company, too. I bought it because WT-300 was less expensive compared with Rexon. I bought it at 30,000yen (250US$). There is not a problem in case of practical use in the lathe. However, there was a point which is dissatisfied with the small place with the price being low. I enjoyed their improvement, too. An extension pipe is attached to WT-300. It is possible turning to length 900mm. I installed an extension pipe and attempted to make the base of the tool rest move. The base got not to move in the connection part of the pipe. The key which is in the pipe reverse seems not to go along a ditch. It moved smoothly when I was shaving the tip of the key circularly with the file.

The motor vibrated when turning on the power. The motor was mounting on bent steel plate base and a tension adjustment bolt, too, is attached.

But, there is not a tension bolt in the center of the base. Therefore, I installed a pull spring in the base and fixed it on the work bench. Moreover, it inserted the wedge which reduced to 3 degrees under the motor base of the side of the shaft. With this reorganization, the vibration decreased sharply. Also, the necessity to loosen a tension bolt in replacement of the belt, too, passed away. In the spring, it is the recommendation of me. |

|

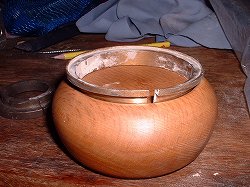

Nov. 09/2003  The Ring-chuck is famous. This chuck is good, when turning the portion of bottoms for a bowl.

The Ring-chuck is famous. This chuck is good, when turning the portion of bottoms for a bowl.I made Ring-chuch using the nut of 3/4"*16tpi, and the plywood. I made 280 mm diameter and 180 mm kinds. and It three nuts M6 with the nail have been embedded in chuck.

I used Ring-chuck for the making cup for cold sake. It was easy to use very much. I thinks that I often use this chuck in the future. Memo |

|

Dec. 06/2003  One of the technique of the wood turning includes buffing.

One of the technique of the wood turning includes buffing.Popularly, it puts a buff to both head grinders and it polishes it but then, the big one can not polish. I found "3-ON LATHE MANDREL" if looking for the Internet. It installs three cloth buffs in mandrel of 3/4" and it is the one to give a lift at the lathe. I bought a length screw immediately and I made it. The screw is 5/8"*285mm. The chucking part is M10 bolt. Also, the pipe of the spacer is using 15ASUS304sch#40.

The buff will use the soft one which is made from cloth. I bought three kinds of polish bars by "Off-Corporation". It is "Tripoli bar" for the first finishing, "White bar" for second finishing, "Carnauba Wax" for last finishing. Memo Aug. 01/2004

I made the Threading-Jig for the wood lathe. Please click a photograph for details. or Here Oct. 24/2004  I made S-type tool rest. I use it for the making of a bowl.

I made S-type tool rest. I use it for the making of a bowl.The material of post is ø25 mm, SS400. The rest is FB30*6. I intends to make any kind of tool rest which the curve is different from. Please click a photograph for details. or Here Oct. 24/2004  I bought Bantam chuck by Axminstor.

I bought Bantam chuck by Axminstor.I thinks that this chuck is easy to very use. Because, it is possible to do fastening-up at the one hand. In the future, I will make various Jaw. Nov 28/2004  I locks center spindle when attaching chuck.

I locks center spindle when attaching chuck.However, it is difficult to have an original lock pin. Especially, the operation is difficult when attaching scrollchuck. Therefore, I mounted an aluminum knob in lock pin.  I mounted one touch lock to open V-belt cover simply.

I mounted one touch lock to open V-belt cover simply.Dec. 30/2004  I made Disk Sander Jig for the Wood-lathe. My workshop is small. However, the power tools are increases.

I made Disk Sander Jig for the Wood-lathe. My workshop is small. However, the power tools are increases.I worried about whether I let's buy a belt and Disk-sander.Therefore, I decided to use the lathe in sander. Please click a photograph for details orHere  I have noticed there being kana sound which is rotating sander jig. It seems that it has come out of the rod of a motor base.

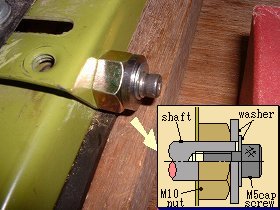

I have noticed there being kana sound which is rotating sander jig. It seems that it has come out of the rod of a motor base.The snap ring is contained in the both ends of a rod. However, it is because there is a crevice in the direction of an axis. Then, I removed the snap ring and converted into the structure which cuts and binds M5 tap tight to both ends. With the photograph, although it was unclear, M10 nut is put into spacer and it just bound tight through the washer. Of course, an opposite side has no spacer. It's become quiet. June 12/2005  I inserted the nut of the bearing adapter in main spindle before. Now, the swing of the principal axis became little. However, I can not be satisfactory.

I inserted the nut of the bearing adapter in main spindle before. Now, the swing of the principal axis became little. However, I can not be satisfactory.I supposed cause. I thought that the surface of the end of main spindle which the nut corresponds to was not a flat. I sheared an end surface with the byte. I shaved by about 0.1 mm. I installed and it turned Bantam chuck. The swing passed away. I thinks that the correct swing quantity is dial gage and that it wants to attempt to be measured. This is small KAIZEN. However, I got a big performance.  July 11/2005

July 11/2005I got the dial gauge which the scrap was just like. Because the stand was lost, it reproduced to use it ..managing the use of iron, 10mm length screw of 12mm, an aluminum pipe, and a strong magnet... When swinging of and the bantam zipper was measured, it was about 20Ê. No fault accuracy. |

|

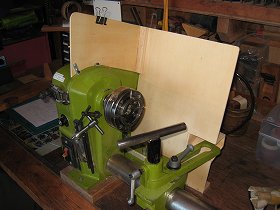

Aug. 28/2005  Last year, I made copy-Jig for wood-lathe. However, the jig could not get high precision. I had the plan which the attachment is composed of to be able to use WT-300 as the trimmer lathe.

Last year, I made copy-Jig for wood-lathe. However, the jig could not get high precision. I had the plan which the attachment is composed of to be able to use WT-300 as the trimmer lathe.I thinks that the bed suits a spindle turning long about WT-300. I seems that it becomes an interesting tool if managing this attachment. Please click a photograph or Here Oct. 26/2005  I received the double angle cutter for the thread cut. It is the one that I was requesting purchase to the friend.

I received the double angle cutter for the thread cut. It is the one that I was requesting purchase to the friend. It is FUKUDA SIKO to make the cutter. The material is SKH51. Sharpness is preeminent. Nov. 03/2005

So-called because they use eight conical white rubber buttons to grip the work and pull it securely back against the aluminium jaw plates without damaging the edge.This is 250mm jaws. Feb. 26/2006

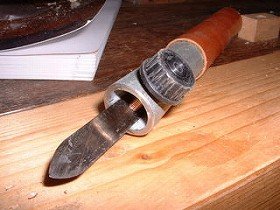

Monotube Improvement.I did not like the hand wheel on my monotube lathe.I remodeled a handle to be able to turn a bar by inserting it.

Good!! Feb. 26/2006

The material is the 15ASGP-W and the blade of jigsaw.I wrapped leather around the grip.

I attempted to draw a pattern on beech.It is good. |

|

Mar. 19/2006

I made Tool rest to use when turninging a box. This material is 30*6 angles.

This is a Long rest. This material is 30*6 flat bar. May 3/2006  WT-300 is a 5 speed change in the V belt.I am usually using 1560rpm for mainly.

WT-300 is a 5 speed change in the V belt.I am usually using 1560rpm for mainly.However, the number of rotations must be sometimes changed.Therefore, I improved for the inverter drive for the number of rotations to be able to be simply changed. Hereafter, My wood turning life will become happier. Please click a photograph or Here July 30/2006  I see eccentric and the twisted works with the turning magazine of the United States.I wanted to make such a work. And, I made this.

I think that it accurately uses this chuck easily very much.

I see eccentric and the twisted works with the turning magazine of the United States.I wanted to make such a work. And, I made this.

I think that it accurately uses this chuck easily very much.Please click a photograph or Here Sep. 02/2006  I made chuck attachment that was able to grip a rectangular material. and,I think that it is possible to use instead of Escoulen-chuck.

Please click a photograph or Here

I made chuck attachment that was able to grip a rectangular material. and,I think that it is possible to use instead of Escoulen-chuck.

Please click a photograph or Here |

|

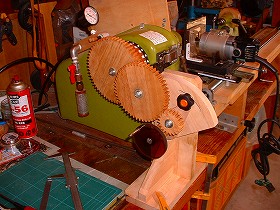

Sep. 15/2006  I made Attachment of index to inlay. I remodeled a face plate on the side of the pulley and I made to be able to do 24 pieces of division.

I made Attachment of index to inlay. I remodeled a face plate on the side of the pulley and I made to be able to do 24 pieces of division.It is Good!! Dec. 10/2008  The 48 pieces of division.

The 48 pieces of division.Trimmer Attachment  The trimmer (Hitachi M6) is set in the self-made table.

Please click a photograph or Here

The trimmer (Hitachi M6) is set in the self-made table.

Please click a photograph or Here |

|

Jan. 7/2007  This is the rotary joint which connects the air hose and the spindle of WT-300.

This is the rotary joint which connects the air hose and the spindle of WT-300.Vacuum chuck  I made vacuum chuck adaptor.It is general to use the face plate.However, I designed chuck that was able to do mount Akisminstar.I introduces how to make joint and chuck. Please click a photograph or Here.

I made vacuum chuck adaptor.It is general to use the face plate.However, I designed chuck that was able to do mount Akisminstar.I introduces how to make joint and chuck. Please click a photograph or Here.

Mar. 1/2007 I received a Vacuum pump by the recycle shop. I connected pipeing and I tested. It is very good. |

|

Mar. 24/2007

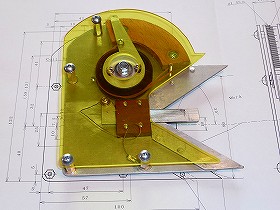

I made sharpening jig for gouge. It forms finger nail. Please click a photograph or Here. May 13/2007

I made parting tool with thin blade.It's 1.5 mm thickness. Material SKH. This tool cuts a narrow ditch. The timber doesn't become wasteful when using this tool.

The Coving tool is simply round stock sharpened at a 45 angle.I made this with drill. I use ø2m/m and ø3.4m/m usual.

This is tool to draw a texture pattern.I used the part of the gear pump. Please onmouse picture. |

|

July 26/2008

The trimmer (Hitachi M6) is set in the self-made table.The slide table moves smoothly.  It inlays the salad bowl.It is possible to inlay easily if this attachment is used.

It inlays the salad bowl.It is possible to inlay easily if this attachment is used. Sep. 23/2008

This is a used 3-jaw chuck. I used a face plate to mount for the wood lathe. Face plate price 2100 yen.and Drilling three of 11 mm.Tighten the three hex bolt of M10. Nov. 21/2008

This is switch to reverse a spindle with inverter.It uses in the finish of sanding. Dec. 20/2009

I made Router lathe 4 years ago. This time, I add Synchronized Gear unit to it. This unit will contribute to my wood turning. Here Jan. 09/2010

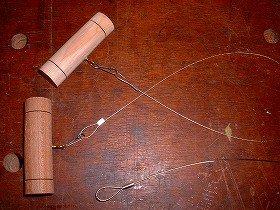

I made wire burner by use 0.5mm and 1mm wire. The snapshot can transpose by wire. Apr. 10/2010

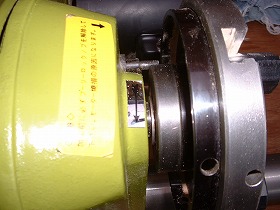

The allophone began to do from the rotation center. Then, it decided to replace a bearing.

Bearing No. is #627ZZ.

It quieted down. Jun. 26/2010

Hollow master by robert sorby.

goblets buff. This is used in the bowl. Jul. 31/2010

I made a table to load down the pipe bed of woodcraft lathe WT-300 with the power drill. Here Feb. 13/2011

I made the ring tool and the hook tool. The material is a concrete-nail. Diameter 3.8m/m and length 75 mm. Here Mar. 3/2012

It bought this smock from the Axminster company in England. Apr. 8/2012

I made a Spindle caliper. It is easy to be used because it is small. Here |

Generally, Expert are chucking for material by the collet chuck and step jaw when making a bowl and a dish.

Generally, Expert are chucking for material by the collet chuck and step jaw when making a bowl and a dish.