Works of wood turning [Page4] |

Lathe & Tool | |

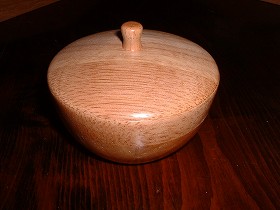

Dec. 13/2003 The Bowl which used laminated wood. I made a bowl and cap for gum tree compilation material with 20 mm thickness. This time, My problem is "buffing "and "Cap ". |

|

|

|

||

1.I cut a 120 mm square by four sheets. Three sheets are for the body and one sheet is for the cap. |

2.I glues together by "Yellow Grew". I puts a lot of Bond glues and I clamp it and drying 1day. |

3.I omits a way of making the body. The manufacture of the cap, turning the hole which puts the collet chuck of ø50mmm, and the paragraph of ø90mm. |

||

|

|

|

||

4.I turn the part which replaces with collet chuck and becomes the outside of the cap. The cap is 2 mm bigger than the body. |

5.I turning to grasp the body with the collet chuck, and to adjust a cap, to push a center and for the cap and the body to unite. |

6.I makes a knob with the same material and turning it to the cap after gluing together. |

||

|

|

|

||

7.I stains it on Watco oil. It is not an end in this. Next, I am un- experienced buffing. |

8.I lift the handmade "3-On Buffs" at the lathe, and rubs a polish bar into the turning buffing wheel. |

9.I used tripoli bar White bar,Carnauba wax for buffing. |

||

|

||||

I think that the preparation process of the wood is important. Because, the lathe line appears when buffing. It is a problem next time. |

||||