Band-saw |

|

Last Update Jan. 3/2016

July 22/2003  I began a wood turning. and, I got to want Band-Saw.

I began a wood turning. and, I got to want Band-Saw.I cuts beforehand square material circularly. I investigated Band-Saw with the non-expensive and high performance. I bought BS-10K by REXON co,ltd. As for this model, the maximum ability to cut is 180mm at 90degrees and 90 mm at 45degrees. It has enough ability to the home user. It is made in Taiwan and it is similar to DELTA. It bought together because the lip fence which is made from aluminum, too, was non-expensive. I made a stand. The height is about 400 mm. It has the caster.  I attempted to use band-saw.

I attempted to use band-saw.Then, dust was flying around. The body of saw has the hose connection mouth of dust collector. However, it comes out from there hardly. Dust is flying from around the table. Therefore, I put a hose to the behind of the table. I fixed a hose with the aluminum plate.  I made jig of the circle cut.

I made jig of the circle cut.It is composed of Lumber and nail. I was drilling 2mm in lumber with 25 mm thickness, it's 5mm pitches. I used a nail for the center of the works in the hole. The guide included in a ditch of miter-gauge is 16mm in width 6mm in thickness. Moreover, the board for stoppers is attached to the side. The photograph is the behind of jig.

Using.

It had become the evening when making a stand and jig and duct of dust.

It had become the evening when making a stand and jig and duct of dust.I attempted to cut some beech last. The sound is quiet, It isn't fearful when using jig. Probably,I think that I will use band-saw most often in the powered tools. Sep. 28/2003

I made the bearing guide. Material is an aluminum board.

It is such touch when it assembles. I think that a guide supports a braid certainly and its cutting accuracy also improves. Dec. 6/2009

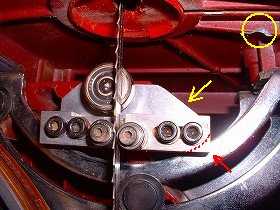

I remodeled Bearing guide. It reversed guide in the lower part to tilt a table.A thrust bearing is the upper side. A radial bearing is the lower side. Cut down a part of an arrow and a round sign. It is part number 2. Drawing Oct. 11/2003

I removed the tension roller of a drive belt. After removing tensioner, a stud pin becomes obstructive for hanging a tension by movement of a motor. I made the phi5mm hole in the center of a stud pin using the drill. And I folded the stud pin using pliers. Vibration was lost after removing tensioner. And the shake of a table was also lost. Oct. 12/2003  I was installing the dust-collecting duct in the bottom of the table of band-saw.

I was installing the dust-collecting duct in the bottom of the table of band-saw.But, the efficiency was not good. I attached in the undershirt bearing guide with the scraper for cleaning of a blade. The material is a 2mm aluminum plate. Since it was easy processing, processing of a plate was completed in about 30 minutes using the saw and the file. Firing urethane is stuck on an aluminum plate and it is completion.

I set to the bottom of a table. I have not used it yet for a long time. However, I think that an effect is large.

Nov. 03/2003 The braid-sweeper whom I made last time was mistake. Dust has not been collected. Probably a coarse particulate is accelerated in a bearing guide, and I think that it is carried into the inside. Then, the dust-collecting duct was installed in the bottom of a bearing guide as an ultimate weapon. Material is the elbow and crevice tape of 25 A-PVC. The slit of width grade of 3mm along which a braid passes is put into the center of an elbow, and the rest is cut little by little so that it may stick to a bearing guide by the present. A crevice tape closes the crevice between a slit or some.

I processed the 10mm PVC board and attached in the safe cover of bansd saw. The elbow and the PVC board are stopped with the set bolt of M4. I want to attach on an elbow the big mouse which collects dust more efficiently. Let's introduce it next time. I used band-saw several times and checked the effect. Almost all dust are inhaled by the duct. I think that my workshop becomes beautiful. Nov. 08/2003  I bought spare-blade. It had been rumor about because it is sharp.

I bought spare-blade. It had been rumor about because it is sharp.The blade width is 16mm and 8mm. And the test cut was carried out. It is preeminent for sharpness as rumor. Especially 16mm is wonderful. A drift is few and cut is straight. Sep. 27/2009

Recently, I am using the blade of Timber-Wolf. I thinks that it is the best. A drift is none and cut is straight. Timber Wolf Oct. 10/2004

The circle cut jig which I made before corresponds only to the diameter of 600mm. Therefore, I made the jig which can manufacture a big radius like rocking chair and the leg of Nobbyhorse. I assemble 2*2 to the L letterform and adjusts the height of the leg to the table. The tip of the leg makes T to be stable.

I mounted the plate to fix on the table of band saw in the tip of the one. The plate is an aluminum material with 5 mm thickness. I think that it is very easy to use this jig. There is no level difference in a cutting. and It's smooth curve.

I made a nobbyhorse(the 1476mm radius) using the jig. This jig is possible to cut to 1800mm radius. The details let's see making a Nobbyhorse. Dec. 23/2004

I picked up the flexible duct of 100 mm. and I mounted in exhaustpipe of band saw immediately. fitting of the hose tip is the one to have combined two plastic plant pots.

It is the photograph which connected with the duct of the exhaust fan to have been composed of for the wood lathe. It is possible to store compactly because the retractility is good. Jun. 10/2007

I mounted the feather board which was made for Bench Jointer in BS-10k.

The screw seat is 15 mm aluminum. Dec. 6/2009

I bought Dustcollector of KERV in August, 2008. Then, I connected the duct of BS-10K.

This time, it remodeled a blade sweeper. The hose can penetrate a door and connects with the Dust port. |